High-pressure pumps for ZLD and MLD reverse osmosis applications

High-pressure pumps deliver up to 90% efficiency

Substantial amounts of fresh water are consumed in modern society and all too often poorly treated industrial wastewater is discharged into the environment.

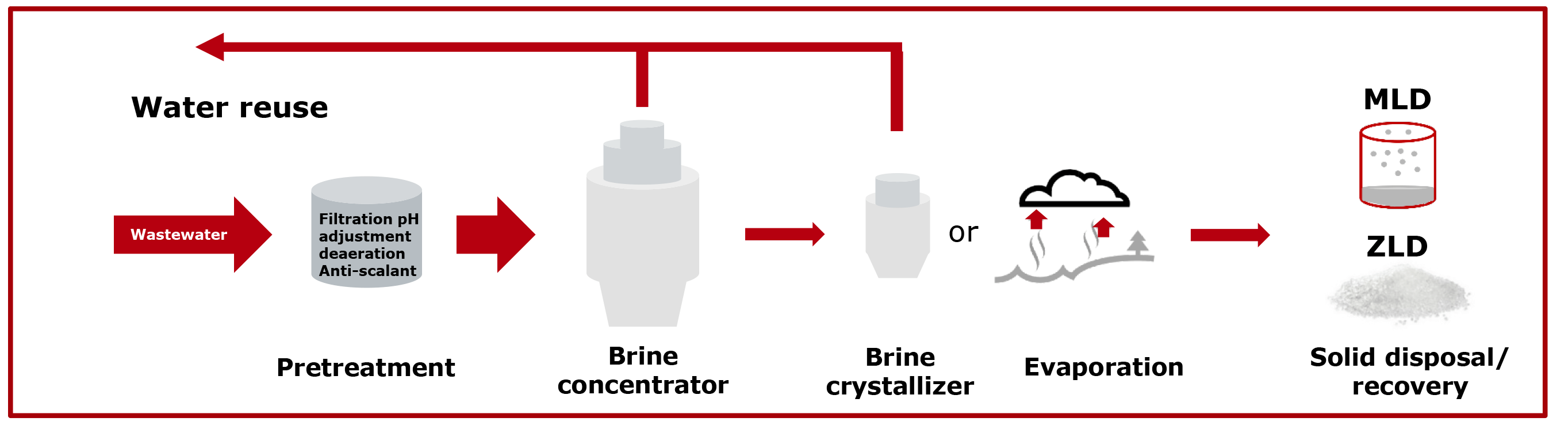

To improve the reuse of water and reduce the discharge of industrial wastewater, Zero Liquid Discharge (ZLD) and Minimal Liquid Discharge (MLD) have emerged as highly efficient wastewater treatment processes. ZLD and MLD are ambitious wastewater management strategies, which eliminate/reduce any liquid waste leaving the plant or facility with most water being recovered for reuse.

The efficient reduction of effluent makes the ZLD or MLD processes highly attractive to industries and utilities. Until now, however, the processes have been constrained by high costs and intensive energy consumption.

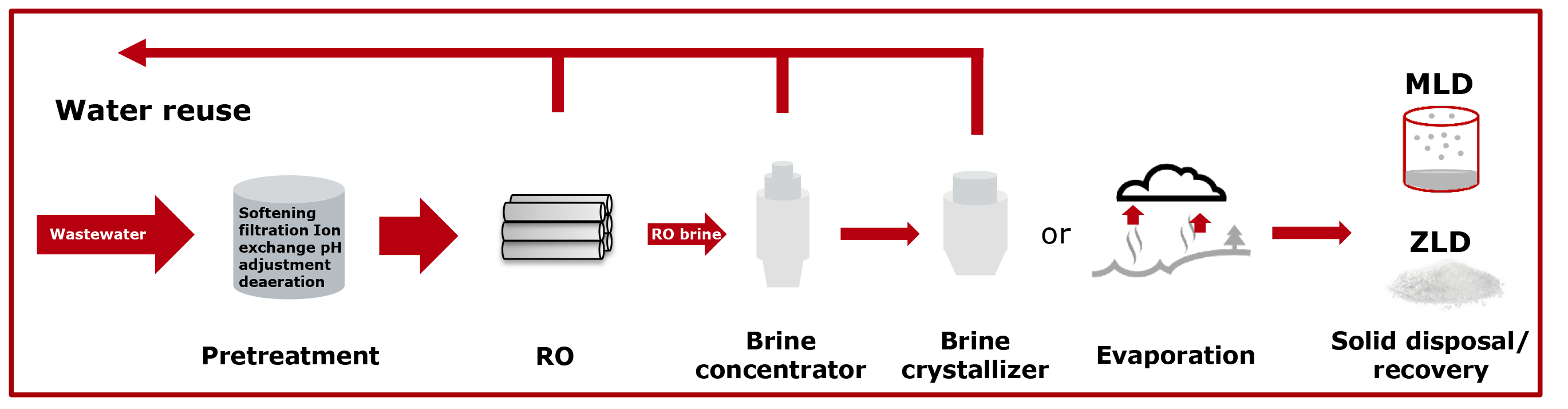

The traditional thermal-based process used in ZLD/MLD systems is highly energy intensive. By adding a membrane-based process, studies show that energy consumption can be reduced by up to 75 %.

The membrane-based process, also known as reverse osmosis, requires membranes and a high-pressure pump that can operate with pressures up to 120 bar. Membranes have been developed for pressures up to 120 bar and with the Danfoss APP W HC pump, professionals now also have access to a reliable and high-efficient pump that meets the requirements of the membrane-based process.

With efficiency rates up to 90% at all operating points, the Danfoss APP W HC pumps are designed to produce the highest level of efficiency in ZLD (zero liquid discharge) and MLD (minimal liquid discharge) applications. The strong and extremely robust pumps are made of non-corrosive materials and guarantee high reliability and low operational costs over the service life.

The pumps are positive displacement pumps with axial pistons that move a fixed amount of water in each cycle. Flow is proportional to the number of shaft revolutions (rpm). Unlike centrifugal pumps, the APP W HC pumps produce the same flow at a given speed no matter what the discharge pressure.

The simple pump design allows easy installation, inspection, and maintenance. Furthermore, the pump operates without oil to prevent contamination.

The APP W HC pump handles flow ranges from 11 to 24 m³/hour (48-106 gpm) and pressures up to 120 bar (1740 psi). The pumps can be parallel-coupled in trains to fulfill the required capacity at any time.

Features and benefits

![]() World-class efficiency – up to 90% at all operation points

World-class efficiency – up to 90% at all operation points![]() Low complexity with few moving parts

Low complexity with few moving parts![]() Easy to operate and maintain

Easy to operate and maintain![]() The pump is oil-free to avoid contamination

The pump is oil-free to avoid contamination![]() Easy scalability when coupled in parallel

Easy scalability when coupled in parallel![]() Made of first-class Duplex steel to prevent corrosion in agressive environments

Made of first-class Duplex steel to prevent corrosion in agressive environments

Save energy with a membrane-based process

Most ZLD/MLD systems are operated with a thermal-based process as standard. This process puts a great demand on energy consumption, making it a very expensive investment

One way of reducing energy consumption is to reduce the amount of water that needs to be evaporated by changing from a thermal to a membrane-based process. This is supported by studies that show an efficiency gain of up to 75% when going from the thermal-based to the membrane-based process.

Related products

Energy recovery devices for reverse osmosis applications

The 3-in-1 Energy Recovery Device (ERD) optimized for sea water reverse osmosis applications.

APP pumps

The APP pumps are designed for SWRO in land-based and marine applications, offering the highest efficiency rates in the industry. The compact design, long service intervals and reliability of the APP makes it a first choice for small and medium-sized desalination plants.

STEMAN Sensors s.r.o.

Hradní 27/37

710 00 Ostrava 10

IČO: 03674690

DIČ: CZ03674690

Telefon:

+420 596 220 199

+420 702 165 774

Email:

steman@steman.cz